Boat Build Series: Engine and Drives Assembly

In the first boat build series, we focus on engine and drives asembly. With our hull now out of the mold, we proceed to our assembly factory and the first stage of our production line. In this initial stage, the first and most crucial step is to level the hulls. Doing so ensures that all subsequent processes are carried out with precision, allowing us to take reference measurements and install equipment in their designated locations. Alongside the leveling of the hulls, we also perform our first out-of-mold QC inspection to assess the quality of the hull surfaces. This is just one of many quality assurance steps to follow throughout the construction of each hull.

With our hulls leveled, being the inaugural build of the M37 series, we take time to double-check our measurements and mark our design waterline and centerlines. These references will serve as the baseline for all assembly measurements to come. Subsequently, we commence the task of locating and marking our engine mounting positions and transom pass-through. Having meticulously leveled and aligned this initial set of engines, we further enhance this by creating fiberglass skins. These skins ensure 100% precision in aligning all future builds and expedite the alignment process.

While these tasks are underway around the transom area, our boat build progresses by measuring and cutting all hull penetrations and proceed to install through-hulls and seacocks. Through thoughtful design, we’ve ensured that only essential fittings are positioned below the waterline, and where feasible, these fittings are mounted through monolithic (non-cored) areas of the hull. This design choice provides added security against leaks into and within the hull’s laminate.

Now that the drive penetrations are accessible, it is best practice to effectively seal the openings with vinylester to prevent water infiltration into the core. We employ a two-stage sealing technique to guarantee 100% water integrity following the drive installation. Subsequently, the boat build progresses by beginning to fit the drives and engine equipment. The drives are fitted, torqued, and then re-torqued the following day to ensure secure clamping to the hull. Additionally, we pre-fit the exhaust through-passage, oil reservoirs, and other accessories around the engine compartment.

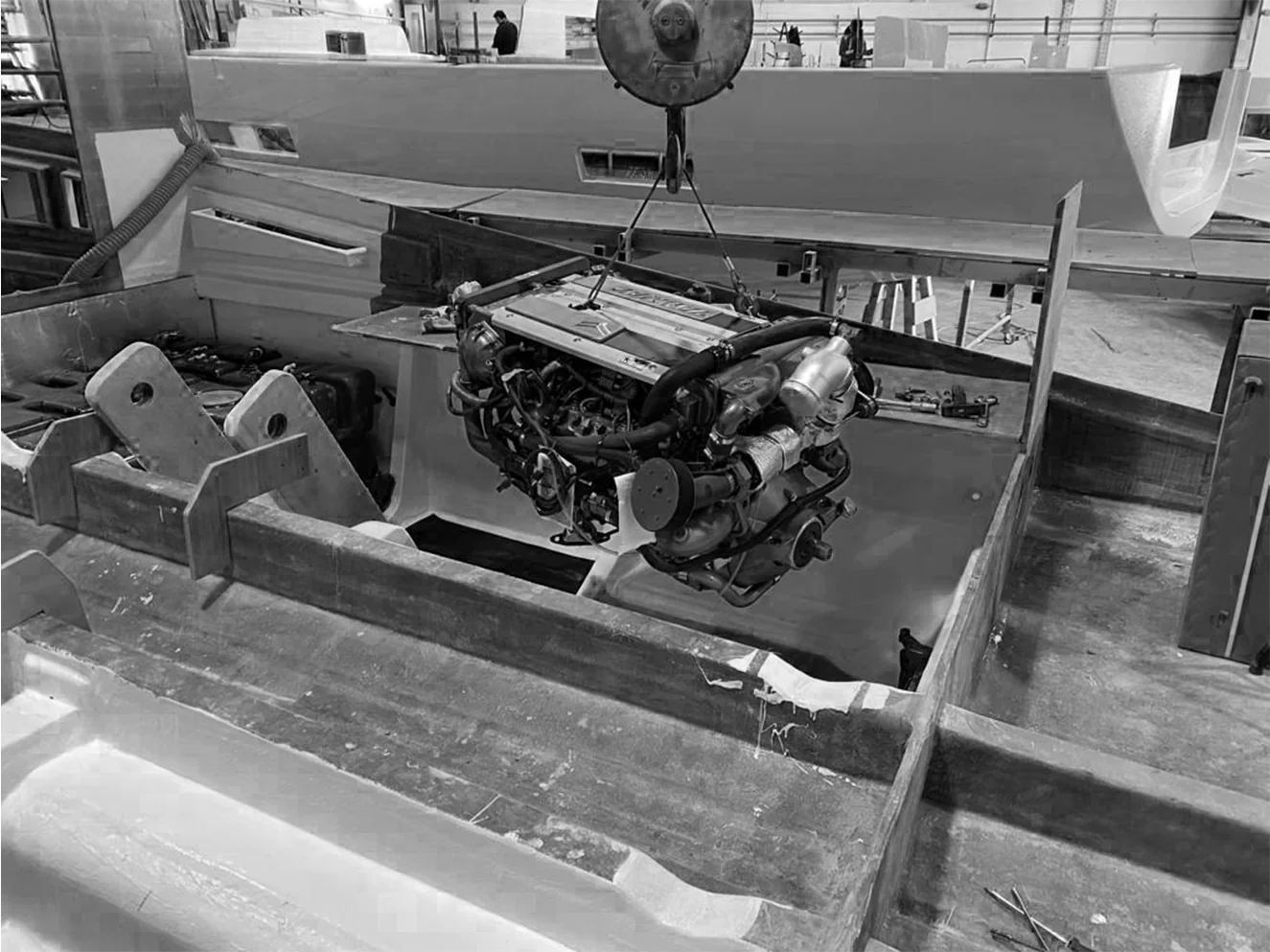

With the engine preparation complete, the exciting phase begins: the installation of our 370hp twin-turbo V8 motors. The Yanmar 8LV370 motors deliver substantial power for their size and weight. We opted for these motors due to their exceptional power-to-weight ratios in their class, primarily attributable to the twin-turbo V8 configuration—a somewhat unique feature for a marine diesel motor. This configuration renders the motor shorter and lighter than a conventional straight 6 installation.

As each motor is meticulously hoisted into place, we capitalize on the precision of our overhead crane to fine-tune the shaft alignment before securing the mounts and locking everything in place. While this extra step may be meticulous, it ensures minimal vibration is transmitted through the coupling of drives to engines—an indispensable step that we find exceedingly valuable.

With both engines now in place, we proceed to install the steering hydraulics, fuel and water connections, along with the installation of the engine ECUs and wiring harnesses. However, the work within the engine room does not conclude here…

Make sure to follow our STORIES and socials to to receive updates on the progress of our next build and further developments.

Have a look at our second boat build STORY