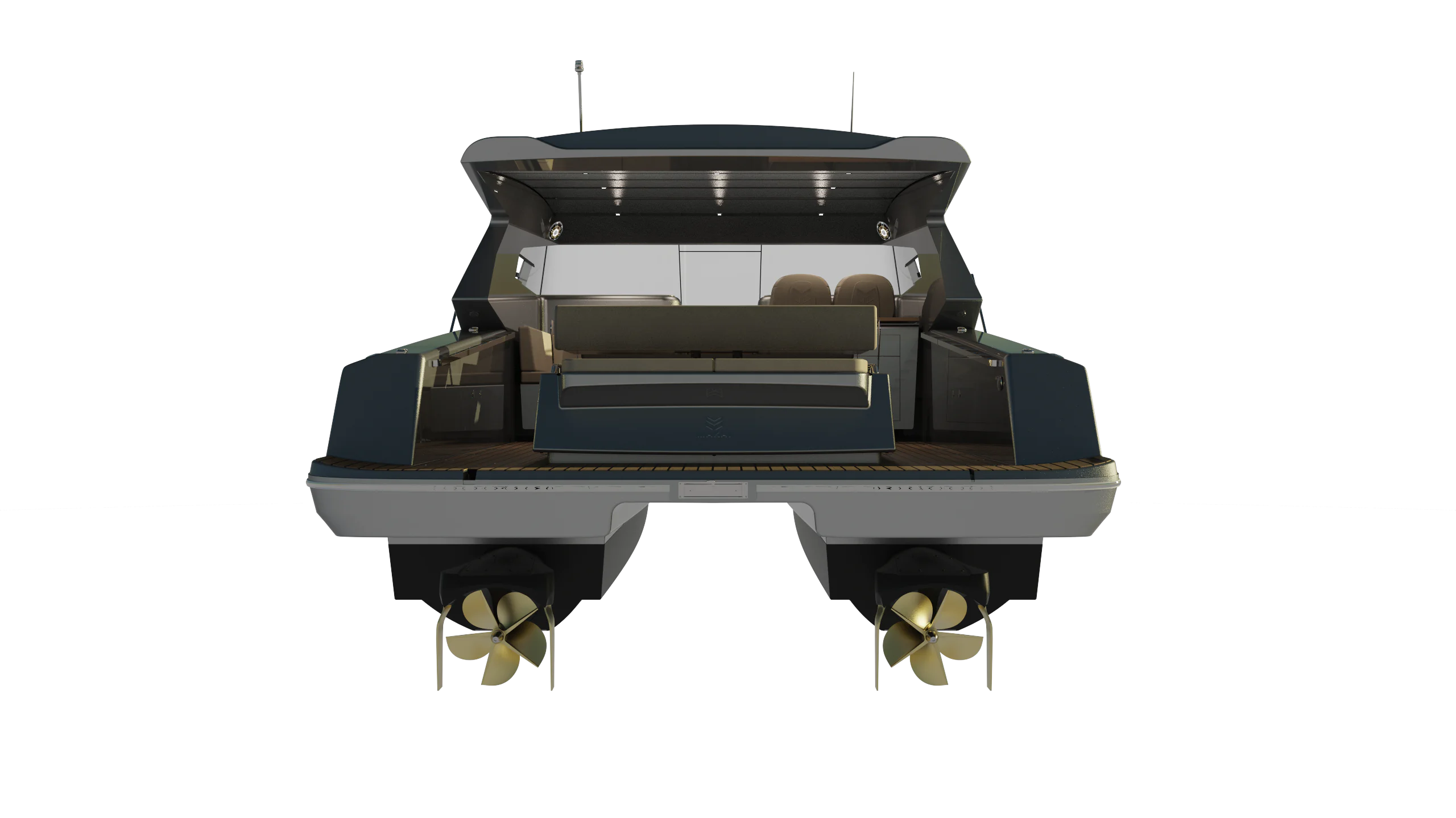

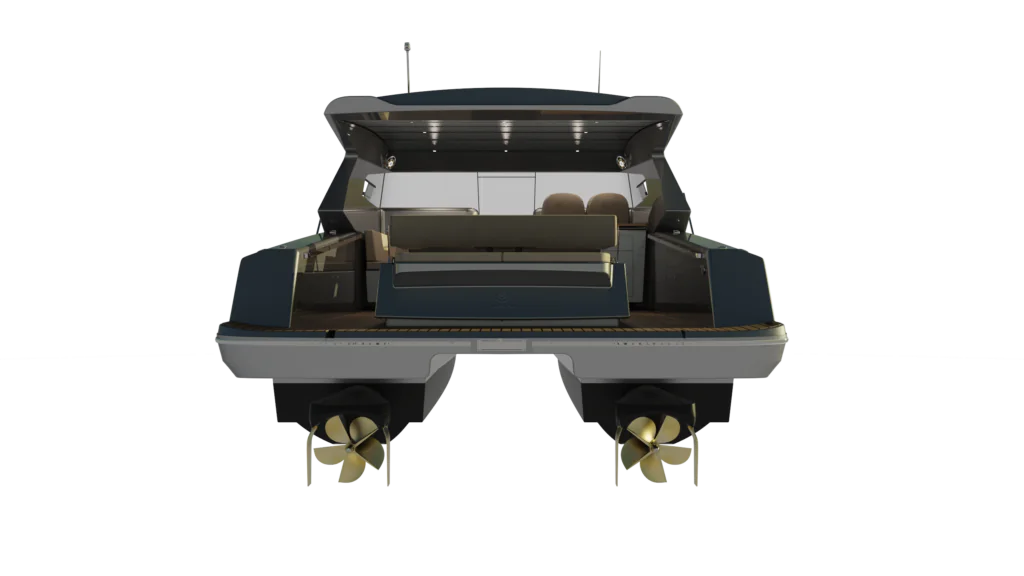

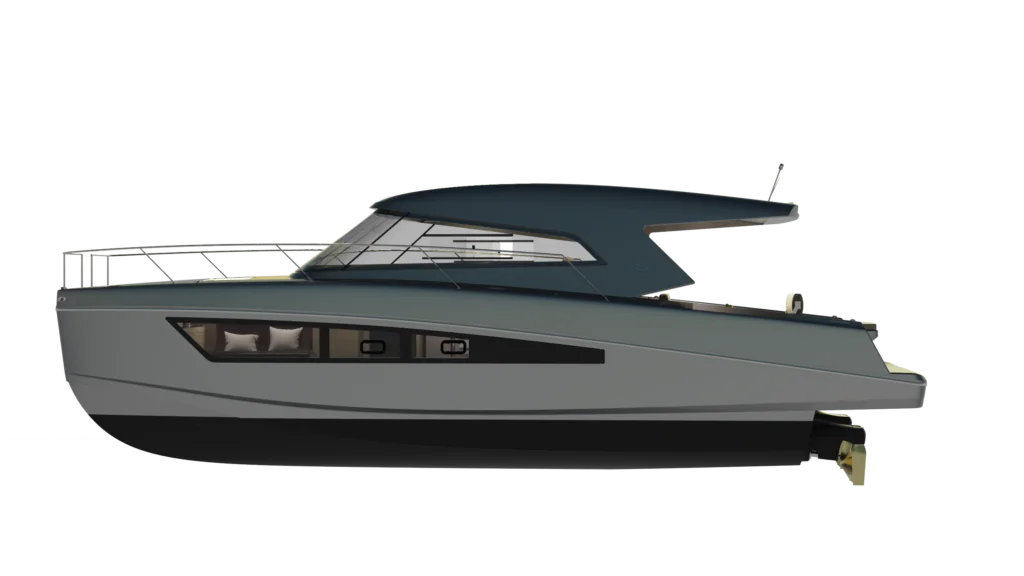

In this in-depth interview with Q-SPD founder Leigh Michau, we discuss the benefits and unique features of the technologically advanced Q-SPD surface drive system and why they pair so well with MAKAI’s power catamaran hull design.

About Q-SPD

Q-SPD is a designer and builder of technologically advanced surface drive systems. Based in New Zealand, the company has developed a truly unique surface drive design that offers increased speed and range through better fuel efficiency, lighter and non corrosive through epoxy composite construction virtually maintenance componentry. MAKAI was attracted to the Q-SPD design because of these advantages over typically complex, metallic surface drive systems that are significantly inferior when it comes to maintenance and longevity.

With several surface drive M37’s now ordered, we took the opportunity to discuss the in-depth design and advantages of the Q-SPD drives and the history of Q-SPD with Leigh.

Could you tell us a little bit about yourself?

I’m Leigh Michau, I am the owner and the designer of Q-SPD surface drives. I’m living and based in New Zealand. I’m a kiwi true blue and I’ve been building drives for boats for like, 27 years or something.

When we were designing the MAKAI M37, we realized that our customers not only care about the fuel economy, and speed of the boat, but also care about the maintenance. Therefore, we wanted to have a discussion with Leigh to learn more about surface drives and why this may be a great option for our customers. So, before diving into the technicalities, can you tell us more about your background and your expertise within the field?

So, as I mentioned, I’m a kiwi born and bred in New Zealand. I’ve grown up in and around the city. So that’s been my life, all my life. I have a passion for boating, in particular. Some 28 years ago, I learned about this technology of surface drives. I worked with some other people on some surface drive projects for a while. But then, I decided that I just wanted to do my own thing. So, effectively surface drives have been my life for the last 20-something years. It’s something that has been a passion right through. And no doubt, we’ll discuss some more of these aspects of why that is the case, as we work through today.

So what inspired into designing the Q-SPD surface drives?

Okay, so been working with some other surface drives, I got to know what surface drives are out there. At the time, there was not really that much known about surface drives, not a lot of people really knew about them, they were mostly used for racing and very high-performance boats. Some people were trying to use them for lower speed. When I’m talking about the high speed, I’m talking about, you know, 80-100 knot boats, real high-speed stuff. That’s what they were traditionally designed for, but not so much for the everyday boater if you’d like. So I worked through a process with some other people in finding out how that could be changed. But we need to take that a little bit further too because of a lot of aspects, particularly with niche-type propulsion and the things like maintenance. I was at the same time starting to investigate the whole concept of using composites, and no one was using composites in propulsion. And not really still, to this day, except me. So the whole concept here was to find ways to reduce the weight and minimize maintenance. After a bit of experimentation, we found that it was actually possible. So that’s when I set up and decided I needed to make this all happen and basically design out some of the negative idiosyncrasies of systems that already existed if you like.

So you mentioned a weight advantage, what would you say is the main differentiating feature? What is the biggest advantage of choosing the Q-SPD surface drive?

Well, I mean, the biggest difference is the fact that it’s made out of composites. So, as I said, that does obviously make it lighter and reduce the maintenance, but that’s not all. There’s more to it than that, I needed to also make something that was entirely low maintenance and that was going to be very user-friendly. Because the last thing we want to do is have to get into a boat and have difficulty operating it. So it had to be really user-friendly, that was one aspect of it. So there was about a lot of experimentation and learning how to set up a system that didn’t need the operator to play with, like using trim, etc, to make it work and get what they needed from it. So the result was a fixed system that was very, very easy to use. And that basically just worked every time, it has to work every time! Surface drives do have their own idiosyncrasies, and there are certainly aspects about the propellers and the relationship of the propellers to the boat and to the water and everything else, which is very different than other propellers. So that all has to be taken into account.

So you discuss a bit about the design, could you elaborate a bit more on how the design of the QSPD surface drives improves the longevity?

So obviously, building out of a composite that cannot corrode is going to last forever compared to any metal basically. Obviously, we have the need to integrate metal parts, because you can’t do everything with composites. So, anything else is basically a high tech, marine metal of some description, whether it be marine stainless steel, or, or bronze. But also we’ve taken that a step further. For example, all the external bearings on the drive unit are all water lubricated. So there’s no maintenance to those, none needed at all. And then any other components that are more sensitive, such as thrust bearings, that use grease, oil, or anything like that, we take inside the boat, and they’re not hanging outside the boat in the water, just like on some other systems or even like on sterndrives, etc, where everything’s hanging in the water and everything can be very vulnerable, we try and take all of that inside. So all your steering componentry, all your mechanics, all your hydraulics everything is inside the boat out of harm’s way, where it can be looked after much more easily.

So when you answered this question about how you compare the QSPD to other drives, you’re really talking about how that compares to other surface drive designes. How would you say the QSPD surface drive compares to the regular shaft drive?

Regular shaft drive? Okay, so in many ways it’s similar because we still use a straight shaft, we use a cutlass bearing like a shaft drive would use. We have rudders with water-lubricated bearings, which is often the same way as a standard shaft drive boat, so you can kind of start to understand where some of this longevity comes from as those parts were using technology that has always been really well proven in those areas. Where it differs is the propeller and how the propeller works and where it’s placed. So, with a surface piercing prop being placed on the water that’s higher up, you don’t have as much sort of gear hanging in the water and you’ve got way less drag. We also take that one step further. Of course, it’s not quite so easy to package something like that and pull it out on the back of a boat. So it’s got to have a structure to hold it all together, which obviously is the purpose of housing. Then,, because the surface propeller is working in a ventilated environment rather than a cavitating environment like a normal propeller, then the requirements are different for that propeller. These differences include where it lives, how it lives and how it behaves.

So can we just ask, if, if there are so many similarities with shaft drive? Why wouldn’t you just use a shaft drive? Obviously, so many boats do use a shaft drive. So what do we gain here?

Well, the first thing you’re getting is a performance gain and that’s really what it comes down to. Now in real terms, that performance gain only starts happening from about sort of 25 knots up. At lower speeds, there’s not a lot of difference because shafts tend to be a little bit more mainstream. So, drag is a really really big factor in the performance of a boat as the more gear you’ve got under the water, the slower you’re going to go. So, if we can take all of that, all of those straps, that big long shaft, that big propeller, that big rudder out of the water completely then that’s great, but you have to have something in the water and that’s where the surface propeller comes into its own because it creates the ability to be able to run at much less power with much less strength. However, the other side of it is that a ventilator propeller becomes more efficient than a self-cavitating propeller on a boat as the speed increases so once you get up to planning speeds, then that propeller is starting to get more efficient than a normal underwater propeller. So hence, you’ll never see them on displacement boats, you know, slow displacement boats, you won’t see a surface prop because there’s no point. But certainly on planning boats, as a rule of thumb, in we consistently see 15% to 18% better performance out of a 30-knot boat by using surface drives. So that starts to give you an idea of what the efficiency gains and how much you’re gaining by using that system.

So in summary, you’re gaining either speed or fuel-efficiency. And then essentially, maintenance and corrosion are going to be equal to shaft drive, except for the fact that your housing is composite rather than having a metallic leg. And, you’ve also got a draft advantage.

Yeah, most certainly.

Would you say that the performance benefits of using the Q-SPD surface drives would be suitable for a boat like MAKAI whose focus is on performance and fuel efficiency?

You know, absolutely. I mean, this is what the whole design concept of the MAKAI is, to build a hull that is more efficient. So if you’re going to go to the extent of building a whole hull, that’s more efficient, then why would you not find the most efficient way of pushing it? Yep. And, that’s kind of goes hand in hand, a sort of a logical, logical way to go.

A lot of brands in this size range are typically outboard-powered, so you don’t have the opportunity to take advantage of surface drives. A lot of catamarans out there aren’t designed for high speed and are designed specifically for displacement speeds, so to actually take that a step further and create a real planning catamaran. That’s a new step as well.

And also, kind of as a round-up, could you comment on your impressions of the MAKAI 37 And what do you think about it?

When I looked at the design, I’m going yeah, this is really interesting. What I really like about the boat itself is how open and fresh it feels and you’ve got that amazing sort of open friendly space right throughout. And it’s not pretentious. It’s a straightforward, you know, good looking sporty looking boat that, that that. Yeah, that appeals to me. I mean, well, it appeals everyone, probably. I could tell right from the beginning from the presentations that Shane gave me about the boat. And what we’re talking about was the whole design was built around, maximizing that efficiency and utilizing the best of the best opportunities. So, yeah, that makes sense to me, definitely.

Summarizing why we’re using Q-SPD on the M37 or the key advantages that you get as a user. So we’ve got considerable advantages with corrosion because a lot of the construction is composite. So we’re really minimizing electrolysis potential and corrosion. Maintenance is at a minimum. And obviously, then we’ve got the performance in speed and performance in fuel efficiency.

Just going back to the low maintenance topic. Can we discuss what that would mean? What would you expect to do in a season? So for one year, what do you have to do to the drive?

Okay, so then in your annual haulout? You would, obviously clean it just like you would clean the rest of the hull, and change the annodes.

So If MAKAI customers choose the QSPD surface drive instead of the standard sterndrive, they can expect much lower maintenance and greater performance, to summarise everything?

Yeah, without being totally biased, considerably less. Anyone who has owned a stern drive for a period of time will know that maintaining the stern drive has a cost every year. It also depends on how often they are used and is the protection proper. It’s just that Q-SPD’s are much more forgiving in those areas.

If you found the interview with Leigh interesting and would like to learn more about the Q-SPD surface drives, please CLICK HERE to get in touch as we would gladly discuss this topic with you in greater detail.